eyc-tech Comprehensive Transmitter Measurement Solution — Smart Building / Facility Environment and Equipment

eyc-tech Comprehensive Transmitter Measurement Solution — Smart Building / Facility Environment and Equipment

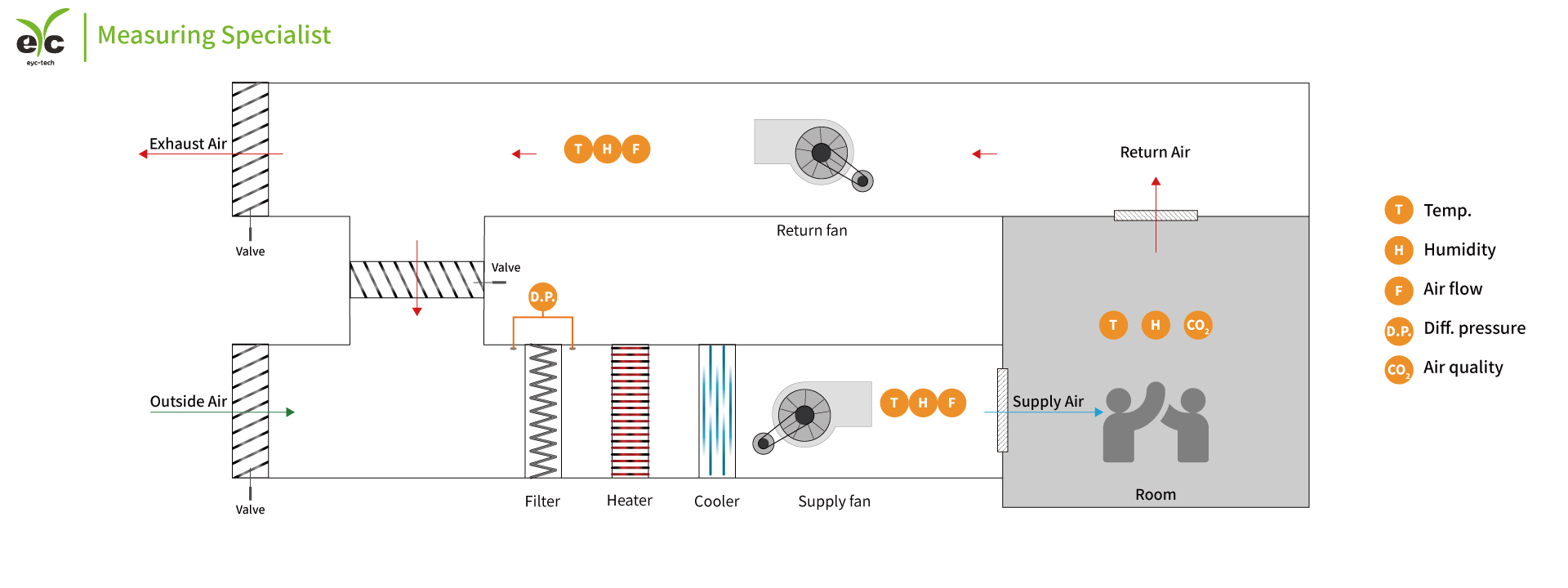

Modern buildings consist of various functional spaces and mechanical-electrical systems, including cooling water, chilled water, ventilation and air conditioning, indoor air quality management, and different equipment rooms. These systems influence each other, and insufficient monitoring in any single part may lead to reduced energy efficiency, increased fan load, unstable indoor environments, or difficulties in maintenance.

Therefore, building management has gradually shifted from single-point monitoring to multi-parameter measurement. By using different types of transmitters to obtain information such as cooling water temperature, air conditioning performance, indoor air quality, airflow, differential pressure, and dew point, data can be sent back to existing control equipment or BMS (Building Management System) / EMS (Energy Management System), enhancing overall energy performance, comfort level, and equipment operation efficiency.

eyc-tech transmitter integration for building system measurement

According to the actual needs of the building system, multiple eyc-tech transmitters are deployed, with complete measurement points arranged across the chilled-water system, HVAC air ducts, indoor air quality, compressed air, filter status, and room pressure differential. Through this measurement framework, managers can clearly understand the operating status of each system and make more efficient decisions based on the data.

Product Implementation Description

• Cooling Water and Chilled Water System: TP01, TP04

Cooling towers, chillers, and equipment cooling pipelines require stable water temperature monitoring to ensure optimal operation of the chilled water system.

TP01 Temperature Transmitter

(2-Wire RTD Head-Mounting Type)

Features : Cost effective. ZERO / SPAN adjustment.

Sensor type : RTD Pt100 (3-wire)

Measuring range : -50 ... 400°C

Output : DC 4 ... 20 mA (2-wire)

Accuracy : ±0.1% F.S.

IP rating : IP30(Housing) / IP10(Terminal)

• HVAC Temperature & Humidity / Duct Environment Measurement: THS13, THS14, THS130, THS140, FTS140

Commercial HVAC systems require continuous monitoring of supply air, return air, and mechanical-room temperature and humidity conditions.

THS13/14 Temperature & Humidity Transmitter Wall type / Duct type

Features : Suitable for HVAC application.

Sensor type : Capacitive Humidity Sensor & Pt 100

Measuring range : Temperature 0 ... +50°C / Humidity 0 ... 100%RH

Output : 4 ... 20 mA

Accuracy : Temperature ±0.3°C / Humidity ±3%RH

IP rating : IP54

THS130/140 Temperature & Humidity Transmitter for Indoor / Duct type

Features : Economic model for HVAC application.

Sensor type : MEMS

Measuring range : Temperature 0 ... 50°C / Humidity 0 ... 100%RH

Output : 4 ... 20 mA / 0 ... 10 V

Accuracy : Temperature ±0.5°C / Humidity ±3%RH

IP rating : IP54

• Filter Differential Pressure and Room Differential Pressure: PMD330, PMM330

Filter clogging and changes in room differential pressure directly affect HVAC efficiency and indoor environmental quality.

PMD330 Differential Pressure Transmitter (Indoor)

Features : Suitable for hospital and clean room; Wide measuring range

Measuring element : Piezoresistive diff. pressure sensor, no flow-through

Measuring range:±50 ... ±10000 pa

Output : 4 ... 20 mA / 0 ... 10 V / RS-485

Accuracy : ±1.0% F.S. ±5% M.V

IP rating : IP65

PMD330 is used across filters in AHU (Air Handling Units), FFU (Fan Filter Unit), and fan-coil units to detect clogging status and plan replacement schedules. PMM330 is deployed in equipment rooms, pipe corridors, and pressure-controlled areas to maintain safe differential-pressure levels and prevent backflow of contaminants.

• Indoor Air Quality and Comfort: THR23, GS23, GM33

Indoor temperature, humidity, particles, and gaseous pollutants are key factors affecting user comfort.

THR23 Indoor Temperature & Humidity Transmitter

Features : Suitable for HVAC and building management system application. Simple appearance.

Sensor type : MEMS

Measuring range : Temperature 0 ... 50°C / Humidity 0 ... 100%RH

Output : 0 ... 10 V / 4 ... 20 mA / RS-485

Accuracy : ±0.3°C / ±2.5%RH

IP rating : IP20

GS23 CO₂ Transmitter / Indoor type

Features : Suitable for HVAC application. Simple appearance.

Sensor type : NDIR sensor

Measuring range : 0 ... 2000 PPM

Output : 0 ... 10 V / 4 ... 20 mA / RS-485

Accuracy : ±40 PPM±3% of reading

IP rating : IP20

THR23 provides temperature and humidity feedback for office and meeting areas.The GS23 provides indoor air quality monitoring indicators such as CO₂ PPM concentration. GM33 is installed in areas with significant volatile organic compound fluctuations, such as pantries and elevator lobbies, to reinforce air-quality monitoring. Through zoned measurement, air-conditioning and ventilation can be adjusted more accurately.

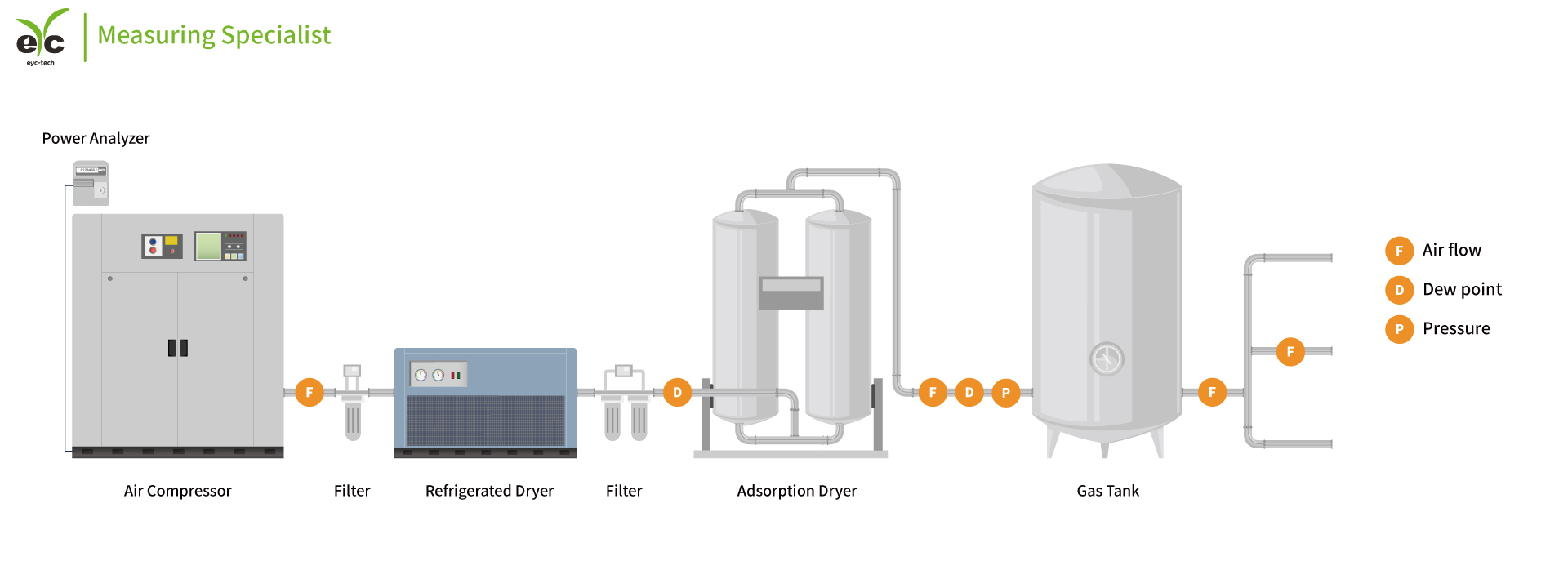

• Compressed Air Dew Point Management: THS88ECO

Building mechanical-electrical equipment—such as damper actuators, automatic control valves, and pneumatic devices—often uses compressed air as the power source. Excess moisture may cause pneumatic components to jam, corrode, or fail.

THS88ECO is used for monitoring the air dew point of the compressed dry air (CDA – Clean Dry Air) system, ensuring stable drying quality, reducing equipment failure risks, and improving reliability

eyc-tech offers a wide range of transmitters, including temperature, humidity, air velocity, dew point, differential pressure, and air-quality measurement, allowing flexible configuration for different areas of a building.

System Operation and Integration

All transmitters return standardized analog signals (4 ... 20 mA) (0 ... 10 V) to the on-site control equipment or the Building Management System (BMS). The central system can automatically adjust the chilled-water flow rate, cooling-tower fans, fan VFD operation, and ventilation volume based on real-time measurement data (such as water temperature, air velocity, differential pressure, dew point, and air-quality indicators), while simultaneously monitoring filter blockage and the drying status of compressed air. The measurement data can be used for energy-consumption analysis, equipment health monitoring, and energy-saving performance verification, making overall management more transparent and facilitating subsequent optimization.

Dynamic Energy Saving and Indoor Comfort Improvement

Through real-time measurement of cooling-water systems, airflow, and air velocity, the building can dynamically adjust cooling towers, chillers, and fans according to actual demand, ensuring optimal operation. Air-quality indicators (such as CO₂ and PM2.5) help fine-tune ventilation rates to enhance comfort while reducing unnecessary energy use. Monitoring filter status and room differential pressure maintains stable airflow and consistent environmental quality across different zones.

Predictive Maintenance and Equipment Reliability

Continuous measurement of water temperature, air velocity, differential pressure, and dew point provides early detection of system abnormalities, enabling timely maintenance and reducing the risk of equipment failure or downtime. The dryness of compressed air and filter clogging conditions are clearly visible, making maintenance more predictable. Comprehensive measurement data supports building energy management, smart-building certification, and ESG reporting, strengthening overall operational efficiency and equipment reliability.