Air-Cooling and Liquid-Cooling Solutions for AI Server Thermal Management

Air-Cooling and Liquid-Cooling Solutions for AI Server Thermal Management

As the power consumption of AI servers and high-performance computing equipment continues to increase, thermal density keeps rising, making the cooling system a critical factor affecting system stability and long-term operational reliability. In practical applications, relying on a single parameter is often insufficient to evaluate cooling performance. Engineers usually need to monitor temperature, airflow, and cooling-medium conditions simultaneously to gain a more comprehensive understanding of system operation. For the commonly used air-cooling and liquid-cooling architectures of AI servers, eyc-tech provides a range of measurement products that can be flexibly selected according to actual requirements, helping users establish stable and long-term thermal monitoring configurations.

TP05 is a temperature transmitter designed by eyc-tech for industrial and equipment applications. It can be applied to temperature measurement in either air or liquid media and is suitable for deployment as a temperature monitoring point in AI server air-cooling or liquid-cooling systems, serving as one of the fundamental data sources for assessing cooling conditions.

Product Features:

● Suitable for air and liquid media

Can be installed around equipment, within airflow paths, or in coolant pipelines according to application requirements.● Supports digital and analog outputs

Allows flexible integration into existing monitoring or control systems as a temperature data source.● Measurement range configurable via RS-485

Enables adjustment of the measurement range based on different application conditions, improving flexibility and reducing reconfiguration effort.● Compatible with the eyc-tech SD05 display module

Can be paired with the eyc-tech SD05 SD05 Integrated Signal Indicator for on-site temperature display, making it suitable for installation on racks or at equipment locations and allowing convenient real-time monitoring of temperature status.Rack-Based Air-Cooling Architecture — Monitoring Rack Airflow via Temperature, Humidity, and Differential Pressure

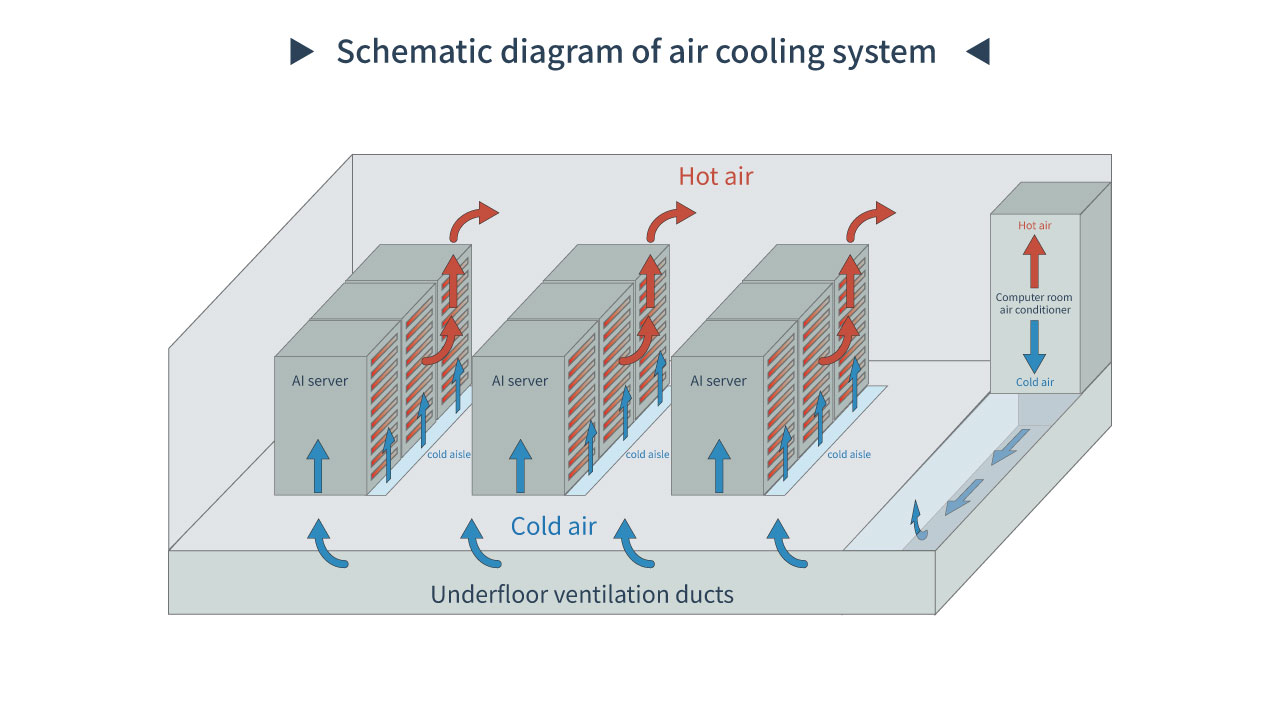

In AI server rack air-cooling architectures, cooling performance depends on temperature distribution, environmental conditions, and whether airflow can pass smoothly through the equipment heat-dissipation zones.

Because airflow patterns inside racks are often complex, differential pressure is commonly used in practice as an indicator of airflow presence and flow resistance changes. When combined with temperature and humidity monitoring, it provides clearer insight into rack cooling performance.

Recommended Measurement Configuration:

TP05 Temperature Transmitter

Measures temperature changes around equipment or at air inlet and outlet locations to track thermal load conditions.

THS17-MD Temperature and Humidity Transmitter

Deployed inside the rack or at the front and rear sides to monitor environmental temperature and humidity as references for operating conditions and condensation risk.

PMM330 Differential Pressure Transmitter

Measures pressure differences between different locations within the rack to assess airflow presence, resistance changes, and air-supply conditions.

Features : Rugged aluminum housing with RS-485 configuration and data logging for precise air and liquid temperature measurement

Sensor type : Pt 100 Class A

Measuring range : -40 ... +200°C

Output : 4 ... 20 mA / RS-485

Accuracy : ±0.1°C

IP rating : IP65

Features : Probe type. Easy to install. Cost effective.

Sensor type : MEMS

Measuring range : 0°C ... +50°C / 0 ... +100%RH (Non-condensing)

Output : RS-485

Accuracy : ±0.1°C / ±1.0%RH

IP rating : IP24 ( Sensor ) / IP 65 ( Body )

Feature : Suitable for HVAC and light industry

Measuring element : Hot-wire type diff. pressure sensor, flow-through

Measuring range : ±50 ... ±1500 Pa

Output : 4 ... 20 mA / 0 ... 10 V / RS-485

Accuracy : ±1.0% F.S. ±4% M.V

IP rating : IP65

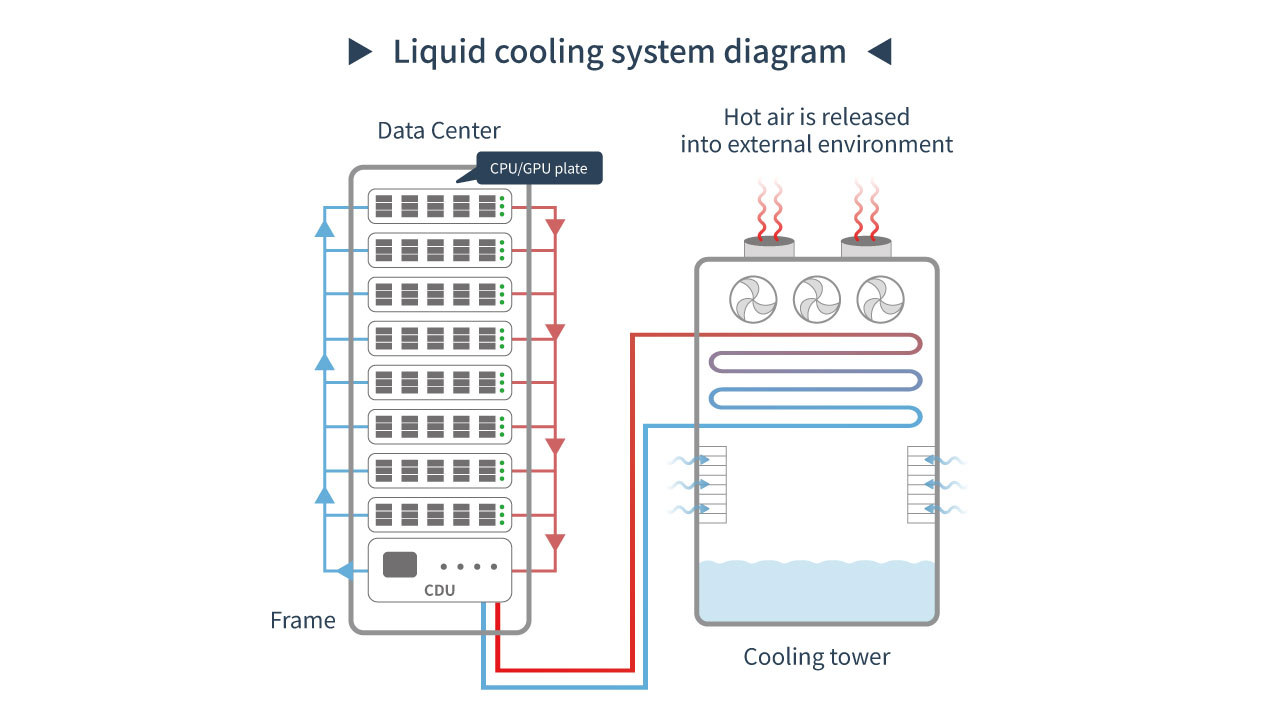

Rack-Based Liquid-Cooling Architecture — Monitoring Coolant Temperature and Circulation Status

In liquid cooling or direct liquid cooling (DLC) architectures, cooling components and coolant loops are typically installed inside the server or rack. Their operating conditions directly affect cooling efficiency and system stability.

Recommended Measurement Configuration:

TP05 Temperature Transmitter

Installed at coolant inlets and outlets or key pipeline sections within the rack to continuously monitor coolant temperature changes.

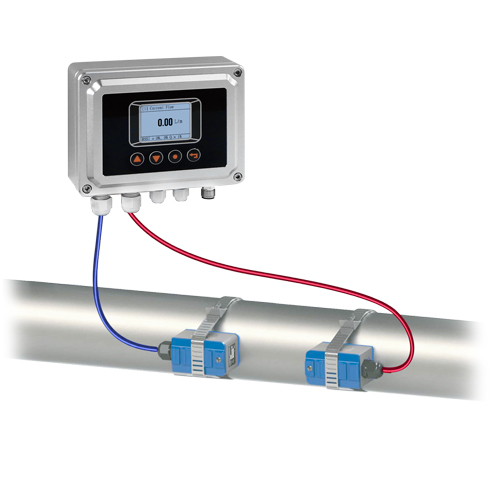

FUM06 Ultrasonic Flowmeter

Measures cooling-water or coolant flow inside the rack using a non-intrusive method, helping verify whether the liquid-cooling loop circulation is operating normally.

Features : Rugged aluminum housing with RS-485 configuration and data logging for precise air and liquid temperature measurement

Sensor type : Pt 100 Class A

Measuring range : -40 ... +200°C

Output : 4 ... 20 mA / RS-485

Accuracy : ±0.1°C

IP rating : IP65

Features : Non-intrusive and high-precision measurement, suitable for various fluids and pipe sizes.

Sensor type : Ultrasonic time difference

Turndown ratio : 100 : 1

Measuring range : 0.1 ... 10 m/s

Output : 4 ... 20 mA / 0 ... 10 V / RS-485

Accuracy : ±1% F.S.

IP rating : IP65

Stable Output and System Integration Support

All of the above measurement products support digital or analog outputs and can be integrated into existing monitoring, control, or management systems as required. They are well suited for the long-term, high-load operating conditions of AI server racks.

Establishing a Clear and Actionable Rack Cooling Monitoring Configuration

Starting from practical engineering needs, eyc-tech provides a comprehensive portfolio of measurement products covering temperature, humidity, differential pressure, and liquid flow. Users can flexibly select appropriate measurement solutions based on rack air-cooling or rack liquid-cooling architectures, establishing a clear, actionable, and long-term thermal monitoring configuration that serves as a key foundation for equipment operation, maintenance, and system management.