Laminar Flow and Overflow

Laminar Flow and Overflow

What is Laminar Flow? What is Overflow?

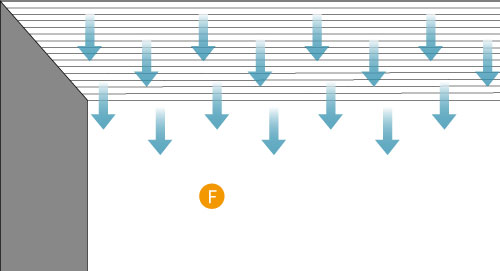

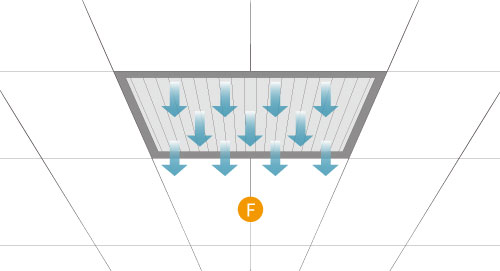

Laminar Flow

Laminar flow refers to a controlled air movement in parallel layers, where the airflow remains steady and uniform, effectively minimizing turbulence and instability. This consistency helps reduce contamination risks and is widely used in air and fluid dynamics systems to enhance overall efficiency.

In cleanrooms, laminar flow ensures high air cleanliness by continuously flushing out airborne contaminants, meeting the stringent production standards required in industries like semiconductors, biopharmaceuticals, and precision electronics. In biological safety cabinets, laminar flow maintains a stable airflow over the work area, preventing contamination from escaping. In surgical rooms, it provides a sterile environment, significantly reducing the risk of post-operative infections.

Key Indicator for Laminar Flow:

According to ISO Class 5 cleanroom standards, the typical air velocity range is 0.3 ~ 0.5 m/s and the ultra low air velocity should remain uniform and stable.

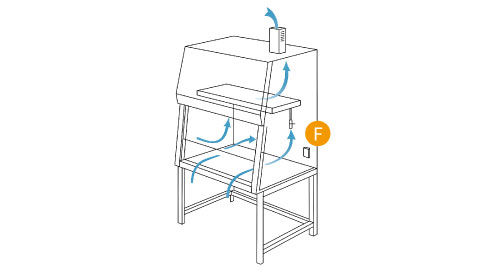

Overflow

Overflow describes the movement of air as it spills or flows outward from one area to another. This mechanism is commonly used to maintain pressure differentials between zones, enabling effective environmental isolation and contamination control.

In negative pressure isolation rooms, overflow prevents the spread of pathogens to surrounding areas, protecting medical staff and other patients. In chemical laboratories,

low airflow overflow effectively contains hazardous air emissions. In high-temperature processing zones, overflow helps dissipate heat, improving cooling efficiency and ensuring stable equipment operation.

|

|

Airflow and Air Velocity Transmitter |

Differential Pressure Transmitter |

|

Measurement Method |

Directly measures air velocity, fast response |

Calculates airflow and air velocity based on pressure difference |

|

Accuracy & Stability |

Provides high-precision spot air velocity measurement, suitable for key position control |

Stable performance, suitable for system-wide airflow trend monitoring |

|

Response Speed |

Fast response, suitable for real-time monitoring |

Stable response, suitable for long-term trend observation and deviation detection |

|

Sensitivity |

High sensitivity, capable of detecting minor air velocity changes |

Detects pressure difference changes, suitable for larger change detection |

|

Installation Requirements |

Installation position is important; recommended to install as per layout |

Requires pipe attachment; suitable for installation on pipes or after filters |

Transmitter Recommendation

The FDM06-L Bi-directional Low Air Flow Transmitter is specifically designed for detecting low air velocities, making it ideal for monitoring airflow in laminar environments. It should be installed in stable airflow zones to avoid turbulence. Key features include:

● High sensitivity for low airflow, dual temperature sensors, ideal for laminar flow / overflow.

● 2" LCD color screen with easy settings via buttons.

● The screen displays airflow and air velocity, integrated with UI settings.

|

|

|

Features : Designed for laminar/overflow monitoring in cleanrooms and pharmaceutical facilities.

Sensor type : Hot-wire sensor

Turndown ratio : 100 : 1

Measuring range : ±(0.00 ... 1 m/s), ±(0.00 ... 2 m/s), ±(0.00 ... 10 m/s)

Output : 4 ... 20 mA / 0 ... 10 V / Relay / RS-485

Accuracy :

0.05 ... 1.00 m/s : ±(1% of mv+0.05 m/s)

0.05 ... 2.00 m/s : ±(1% of mv+0.1 m/s)

0.1 ... 10.00m/s : ±(1% of mv+0.2 m/s)

IP rating : IP65